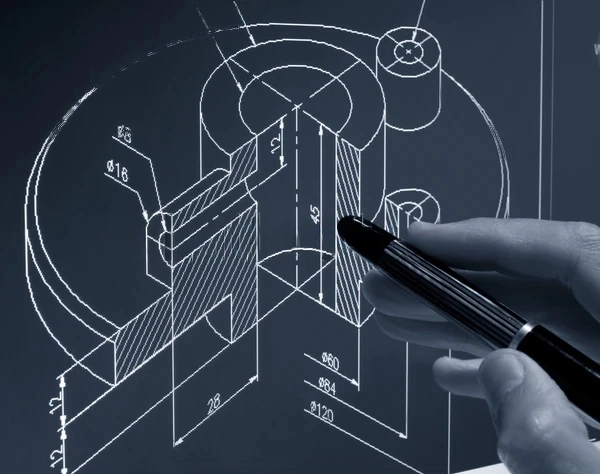

Capabilities of designing parts, sheet metals, surfaces etc. along with the ability to assemble the parts

and produce engineering drawings using the 3D model that’s designed. There are many more functions that can

be done using these softwares. Once you design then there are certain industrial design standards that needs

to be followed to design a quality products that will eventually produce a good quality product, which is

very essential to boost quality control.

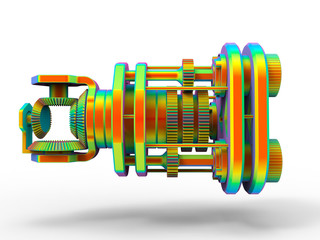

Creo Parametric enables creation of solid, 3D models of a part and assembly models. The advantage of solid

models is that they are realistic visual representation of designs; containing properties such as mass,

volume and centre of gravity. In addition, 3D models can be used to check for interferences in an assembly,

for strength analysis and also for manufacturing.

What are the benefits of using Creo Parametric?

- Powerful parametric design capabilities allow superior product differentiation and manufacturability.

- Automatic propagation of design changes to all downstream deliverables and allows you to design with

confidence.

- Fully integrated applications allow you to develop everything from concept to manufacturing within one

application.

- Complete visual simulation capabilities enable you to improve performance and exceed quality goals.

- Easy to build parts from primitives, extrusions and revolves.

- Facilitates reusing of existing data when creating new parts.

- Makes it simple to analyze parts for stresses or possible failures.

What are the career prospects / jobs roles?

- Mechanical Engineer - CREO

- Product Engineer - CREO

- AutoCAD Engineer